Predictive Maintenance: Predicting Rare Events like Machine Failures

Skills Employed

- Modelling Techniques: Classification Models - Random Forest, XGBoost, Autoencoder (ReLU activation function)

- Cross Validation Techniques: K-fold

- Text Processing Techniques: Preprocessing (Lemmatization, Stop Word Removal, Removal of punctuation, numbers etc.), Keyword extraction

- Other Statistical Techniques: Principal Component Analysis, Upsampling (SMOTE, ADASYN)

- Tech Stack: Python, Hive (SQL)

- Libraries: Numpy, Pandas, Sklearn, NLTK, Datetime, Tensorflow, imblearn, XGBoost

Introduction

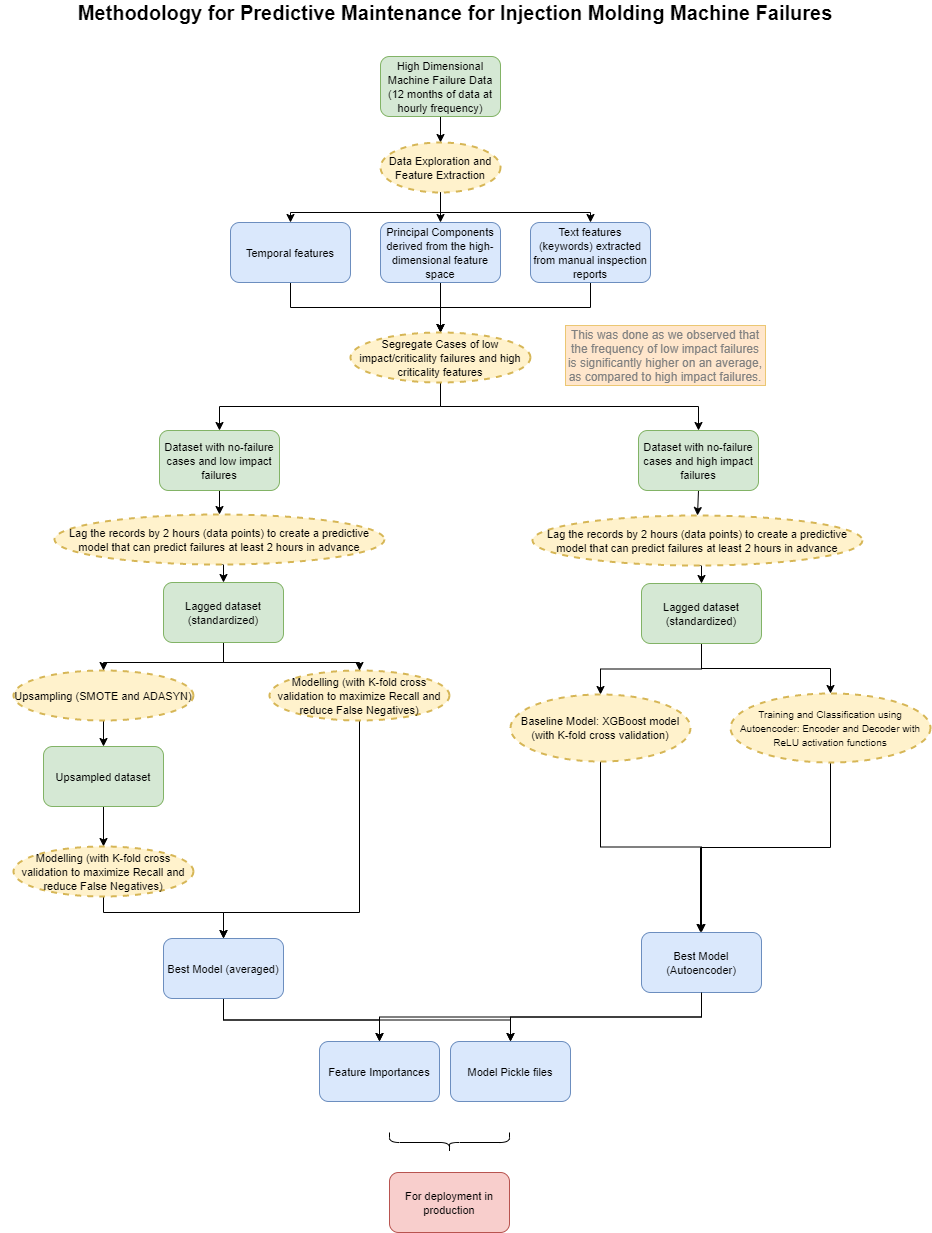

In this project, we tried to solve the critical and rare events of machine failures for a manufacturing giant. The problem is a critical event as any machine failure can lead to loss of production value and thus, effectively monetarily losses for the company. We solved this problem as a proof of concept for a particular plant for the company. In solving this problem, we learnt that the machine failures in this use-case could be categorized as two major types: high-impact events (like component failure, breaks and permanent machine damage) or low-impact events (overheating, pressure fluctuations etc.) We also learnt that the frequency of these events are significantly different. As a result, we followed a multiple-step approach to handle each of these cases separately. The detailed methodology followed in this project is depicted below.

Methodology

The detailed methodology followed in this project is explained below.

Impact

As mentioned above, this project was executed as a PoC which was deployed for 6 months in a particular plant for the manufacturer. The framework could reduce 70% of all failure instances (on ana average) over the course of 6 months. This led to the manufacturer scaling the model up for 4 other plants across the world. The PoC project was converted to a retainer project with a dedicated team for the next 1 year.

References

The following papers and literature (not limited to) were referred to, for execution and solution approach design.

- A. Abu-Samah, M.K. Shahzad, E. Zamai, A.Ben Said; Failure Prediction Methodology for Improved Proactive Maintenance using Bayesian Approach

- Nakamura J.; Predicting Time-to-Failure of Industrial Machines with Temporal Data Mining